The Yukon Territory was built on gold. Founded when tens of thousands of prospectors flooded north during the great Klondike Gold Rush of 1898, the Yukon’s economy continues to rely, more than a century later, on mining for gold and other metals. That comes with some rewards: In the wake of the 2008 crash, while much of the world struggled, the Yukon’s economy boomed, as the skyrocketing price of gold had triggered a second gold rush. But it also comes with risks: the uncertainties of a boom-bust cycle, and the potential for environmental disasters left behind after the mines close.

That’s where Dr. Amelie Janin comes in. Janin, the industrial research chair at the Yukon Research Centre, is working on homegrown, sustainable ways for mining companies to clean up their messes—specifically, methods to ensure that the heavy metals liberated during the mining process aren’t allowed to contaminate the territory’s water, plants, and wildlife.

Currently, the majority of mines use a chemical treatment to neutralize the heavy metals left behind by mining operations. It’s a reliable process: “We know it really well, we can control it, and we know it works,” Janin says. “But it’s not necessarily very sustainable.” Since 2012, she’s been working on a biological alternative, replicating Mother Nature’s own cleaning systems: “We want to try to reproduce the mechanisms that are occurring naturally in the Yukon and use them to our advantage.”

“We want to try to reproduce the mechanisms that are occurring naturally in the Yukon and use them to our advantage.”

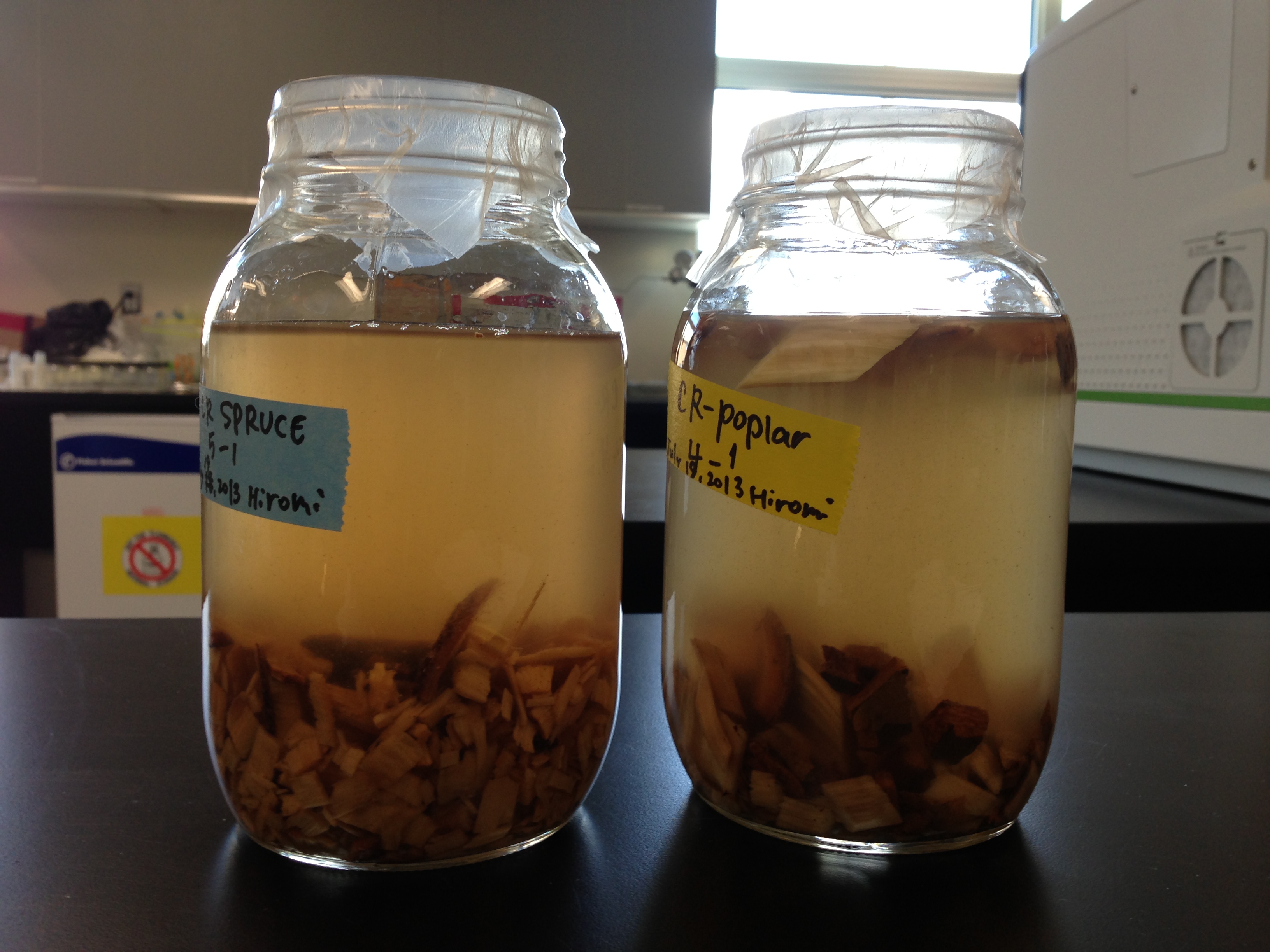

To accomplish this feat, Janin’s created what she calls “bio-reactors.” After gathering sediment from local creeks, which contains the microbes that she needs to use as cleaners, and mixing the sediment with gravel, sand, and other materials—maybe wood chips or biochar—in a sealed tube, Janin runs contaminated mine water through the tube. From here, the microbes simply go to work. Various bacteria have different roles in the process: One of them transforms the sulfate that’s naturally present in the mine water into sulfide. “And then the sulfide is very, very reactive,” Janin explains. “It reacts with the [heavy metals] right away, and then it precipitates the metal. So the metal is solid, instead of being dissolved in the water and transported by the water.” The gravel and other solid particles in the tube act as a filter, trapping the now-solid metals in place.

This is a process that’s also been used and experimented with in southern Canada and the United States, but Janin’s work has a decidedly northern twist: She’s tried the process at colder temperatures too. In addition to testing her bio-reactors at room temperature in her lab, she’s also conducted trial runs inside a fridge, at 37 and 43 degrees Fahrenheit. She’s found that some versions of her bio-reactors still perform well at colder temperatures, while others were negatively affected.

Janin’s bio-reactors are impressively efficient: She’s managed to cleanse more than 99 percent of copper, more than 99 percent of zinc, and between 94 and 95 percent of arsenic from the contaminated water she’s working with so far. That level of efficiency would leave the water on shuttered mine sites virtually unscathed. The next step, then, is to scale the procedure up, from the lab to a full-blown mine site. She’s working with several mining companies in the Yukon, including one that runs an operating mine and one that’s tasked with cleaning up and refurbishing an old mine site. She’s moved up to working with 50-gallon barrels in one pilot project, and has her eye on larger-scale bio-reactors that have been built elsewhere as models.

One way to build a full-scale bio-reactor is to use a constructed wetland. In a separate project, Janin and a partner, Dr. Katherine Stewart, have been researching what happens to heavy metals once they’re trapped in the wetlands.

“A wetland is another biological system that treats water,” Janin says, “and it’s based on the same microbes as the bio-reactor.” The key difference, though, is that wetlands are filled with plants—not just gravel and wood chips. That means there’s a theoretical risk of the heavy metals being absorbed by the flora, and Janin wants to ensure that she knows where, exactly, the metals are going as they’re filtered.

“If we use a constructed wetland to remove [copper and selenium, for instance, from the water], what happens to them? Where are they going? We don’t want the constructed wetland to be a black box, and say, Oh well, that works,” Janin says. “We really want to understand how that works.”

Janin and Stewart were able to determine that 99 percent of the heavy metals isolated in the wetlands remained in the mucky sediment—they weren’t flowing out with the water, or, critically, being absorbed by the plant life and entering the food chain. That’s a hopeful sign for the utility of her bio-reactors, and for locally grounded, biological solutions to mine contaminants more generally.

Metals, Janin points out, cannot be disappeared or eliminated. The hope, instead, is that we can find ways to control the contaminants, keep them static and in a known location—using Yukon-grown microbes for the job.

Dispatches From a Changing Arctic is a biweekly series of reported stories from Alaska and the three Canadian northern territories.