*Listen to the audio version of this story, narrated by Kate Wheeling.

On a broiling February afternoon in Mazamari, Peru, Brenton Ladd waited inside the one-story airport for a Bombardier Dash 8 from Lima. Aboard the plane, Lukas Van Zwieten and Ruy Anaya de la Rosa dozed between fits of turbulence that rocked the tiny plane as it flew over the Andes. The men were Mazamari-bound to collaborate with Ladd—an Australian plant ecologist and professor at Lima’s Universidad Científica del Sur—on a project that involved giving cookstoves to indigenous women from the neighboring town of Satipo. The cookstoves weren’t so different from the traditional stone ones women had been using all their lives, except that they were designed to burn wood and other biomaterials at low-enough oxygen levels and at high-enough temperatures to create something called biochar. In theory, the resulting mixture could be added to surrounding soils to increase nutrient levels, and, eventually, crop yields. Van Zwieten, an environmental chemist, would provide scientific counsel, and Anaya de la Rosa, a project director at an Australia-based sustainability non-profit, would provide logistical support. The project should already have been well underway, but it had never begun.

The plane was an hour late by the time it touched down on the frontier town’s airstrip, a slab of pavement in a verdant sea of grasses and shrubs. The new arrivals stepped off the aircraft directly onto the tarmac, radiating heat in the midday sun, and headed for the cool concrete terminal where Ladd was waiting. Ladd, 45, hiked up his board shorts and embraced Van Zwieten and Anaya de la Rosa in turn, and led the men to his small black Volkswagen, parked on the two-lane road that separated the airport from Mazamari’s urban zone—a few dozen square blocks of buildings bounded by dusty roads and forested mountains. As Ladd navigated the town’s uneven roads, the car’s undercarriage scraped against errant rocks. Van Zwieten and Anaya de la Rosa had endured more than 24 hours of travel from Australia to Mazamari, but Ladd was already heading out of town, beginning the long drive back over the Andes to Lima. On the smooth, lineless highway out of Mazamari, he picked up speed and explained what had gone wrong in Satipo.

(Photo: Kate Wheeling)

“The locals didn’t trust me,” he said, raising his voice over the rush of open windows and the croon of Kurt Vile. Ladd tried to buy half an acre from a grandmother living outside Mazamari for what he thought was a fair price, but the deal ended with her daughter screaming at him over the phone. For a short time, he paid another family for access to their land, but the arrangement ended abruptly after its members couldn’t agree on who owned the land. One man he encountered in the jungle nocked an arrow into his bow, pointed it at Ladd, and told him to go home.

It was easy to see why the locals were wary of the foreign professor. At over six feet tall, he towers over them; he wears tank tops and flip-flops instead of the more formal wear you might expect of a scholar; and, after more than half a decade in Peru, his Spanish is still muffled by a thick Australian accent and chronic misconjugation.

But his intentions are noble, if grandiose. A plant ecologist by training, Ladd was making the 10- to 12-hour trek from the university in Lima to the jungle several times a year, where the slash-and-burn operations of small-scale farmers account for the bulk of Peru’s forest loss. He believes biochar can help farmers there transform the region’s nutrient-poor soil without cutting down trees, breaking a cycle of poverty, deforestation, and harmful carbon emissions.

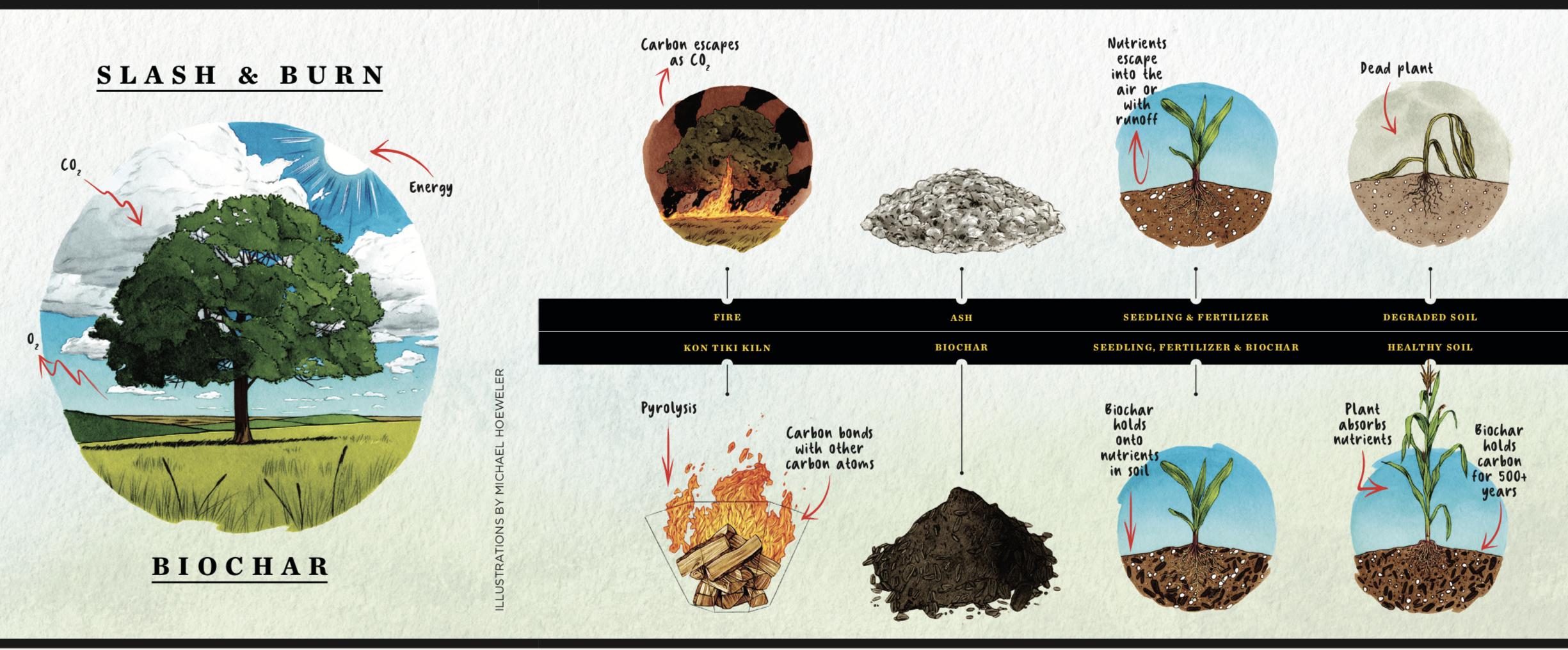

As trees grow, they suck carbon dioxide out of the atmosphere, strip out the carbon atoms to build leaves, stems, trunks, and roots, and release the excess oxygen back into the air. When they die and decay, this process runs in reverse: Carbon atoms latch onto oxygen atoms and escape into the air as carbon dioxide. Mature forests, with their abundance of decaying biomass, eventually begin to release as much carbon dioxide as they take in.

Torching biomass typically only speeds up this release, but if that same material is burned without oxygen—a process called pyrolysis—the carbon takes on a much more stable form. Instead of forming carbon dioxide, the carbon atoms bond with one another, forming super-stable structures that don’t easily break down. Tree trunks, twigs, and foliage all become a shrunken, charred material, pure black and light as air, that smells like the remnants of a campfire and soaks up water like a sponge. It acts as a cache that can hold onto carbon for hundreds, if not thousands, of years.

For that reason, biochar has long interested climate scientists as a potential mitigation strategy—perhaps the least flashy of all the carbon-capture techniques that have been floated as options to combat global warming. One 2010 study found that biochar could offset up to 12 percent of human-related carbon emissions. It’s more technologically feasible than some other carbon-capture techniques, like geologic sequestration, which requires carbon dioxide to be siphoned from the atmosphere and injected underground into old oil or gas wells. But none of these facts have led to its widespread implementation.

Van Zwieten believes the primary advantage of biochar over other climate-mitigating carbon-capture techniques is that it also comes with a persuasive, tangible benefit: Biochar can boost food production in otherwise infertile soil. This is what could power its adoption.

Around the globe, about 85 percent of farmers are small-scale shareholders, with fewer than five acres of land. If all of them, even the ones who have access to decent soil, started using biochar, the cumulative effects on carbon storage could be substantial. But most farmers in Peru‘s jungle, the ones who could theoretically benefit the most from soil remediation, don’t know what biochar is, and neither did Ladd until 2008.

(Photo: William Widmer)

That year, Ladd was in the first year of a two-year postdoctoral position at the University of Bonn in Germany when he befriended Nils Borchard, a soil chemist and, at the time, a Ph.D. student. Borchard was comparing the effects of charcoal and biochar—both waste products of various forms of energy production—on the growth of maize, and he needed a plant scientist to help evaluate the results. Ladd signed on, and quickly found that biochar didn’t make much difference to plant growth.

Ladd wasn’t surprised—or deterred. The temperate soils of Germany are already pretty optimal for growing plants, but, Ladd thought, biochar still might make a difference somewhere else.

Biochar reminded Ladd of something called terra preta—pockets of dark, fertile soil in the nutrient-poor earth of the Amazon, discovered by the soil scientist Wim Sombroek in the 1950s. Sombroek found that the blackened soil is a lucky mix of minerals, microorganisms, broken ceramics, and charcoal that allows crops to thrive where they otherwise might not grow at all. Amazonian archaeologists have unearthed evidence in Brazil, for example, of massive pre-Columbian civilizations that would have been almost impossible without the unusual black soil they rested upon.

Ladd wasn’t the only scientist interested in terra preta and biochar. The climate-mitigation and soil-remediation potential of biochar have the Global Environment Facility—a non-profit that funds climate change projects—committed to getting the material into the ground. The GEF is funding a global project called Biochar for Sustainable Soils (B4SS) to determine which kinds of biochar work best for different crops in different parts of the world versus which ones don’t work at all, and to communicate the soil benefits to farmers. As the B4SS project director, Anaya de la Rosa works with biochar researchers in six countries, including Ethiopia, Kenya, Vietnam, China, and Indonesia. The project organizers tried to find locals and researchers to work with, but when they went looking for partners in Latin America, the only person they found working with biochar was Ladd. Well, we’ll take him, they thought.

Along the narrow, winding highway that connects Peru’s jungle to its coast, Van Zwieten, who had become carsick, took over the wheel. The tropical rains had washed away chunks of the road, and the earthy scent of freshly soaked soil and overripened fruit wafted in through the windows. The group stopped for lunch at a roadside restaurant overlooking the Rio Perené, one of the Amazon’s countless tributaries, in the Chanchamayo province. A macaw, wings clipped, waddled around on the lawn, taking pieces of fried chicken from the hand of one of the proprietors and spitting the breading out onto the ground.

The men settled down into white plastic chairs around a table on the patio and began drinking cool glasses of cocona juice, while Ladd listed all the challenges the farmers here face.

Most of the farmers in the Peruvian rainforest are transplants from the Andes, he explained. (Historically, the jungle’s indigenous populations were hunter-gatherers.) In the fresh, healthy soil of the mountain range, composting wasn’t as critical, Ladd says. Complex agrarian societies thrived in the mountain range’s valleys by building terraced farmland that trapped nutrient-rich, alluvial soils.

“You couldn’t ask for better soil,” Ladd says. “There’s a reason why it was the cradle of one of the most impressive civilizations the world has seen.” But the soil in the jungle is older and more weathered. More than 100 inches of rain wallop this region in an average year, and as the water infiltrates the soil, it dissolves its nutrients. Runoff carries them—and a good amount of soil—away. “Carbon, nitrogen—everything you need to make healthy food and healthy people. You can see it in the river,” Ladd says, gesturing to the brown, turbulent water of the Rio Perené below. Only heavy metals that are not so easily dissolved—aluminum, cadmium, iron—remain. “All the good stuff gets washed out,” Ladd says, “and all the shit stays behind.”

To get by in the nutrient-poor soils of the rainforest, farmers there have practiced slash-and-burn agriculture for centuries, but as the population grew, so did deforestation rates. The slow trickle of Andean farmers to the jungle, which began when the Spanish arrived in the 16th century, surged in the 1980s, when hundreds of thousands of people fled the Andes to escape the violence of the Maoist guerrilla group Sendero Luminoso (Shining Path). Then a mining boom in the 1990s sliced and carved the Andes and the jungle with new roads. The development has opened up the jungle region to outsiders like never before.

The transplants, accustomed to the denuded peaks of the Andes, cleared swaths of forest by slash-and-burn to create farmable parcels of land. The ash fertilizes the soil for a while, but the torched fields only yield crops for three years, Ladd explains, before farmers must abandon them and burn new plots. Today, small-scale agriculture is one of the main drivers of deforestation in Peru, which loses over 700,000 acres of forest every year. It takes at least seven years for burned land to begin to recover—but it can take much longer. “There is forest in the southeast corner of the country that hasn’t been cleared since before Columbus arrived. The indigenous population cleared and farmed it 500 years ago, and you can still see that,” Ladd says.

Now, climate change is rapidly altering the Amazon. Temperatures are projected to rise by up to three degrees Celsius by mid-century, and rainfall is expected to drop. Under these warmer, drier conditions, tropical rainforest can quickly transform into savanna. Forest that’s cleared today may never recover.

“The only possibility we’ve got here is to intervene,” Ladd says.

In an ideal environment, transforming bad soil into good soil is only a matter of applying fertilizer. Animal manures and compost are low-tech, low-cost sources of plant nutrients like nitrogen and phosphorus, but the concentrations of nutrients are hard to control. Synthetic fertilizers allow farmers to apply higher and more precise concentrations of multiple nutrients to their soils.

But synthetic fertilizers are also expensive, and the farmers in the sliver of land between the Puya Sacha cloud forest and the lowland Chanchamayo province—where Ladd wants to introduce biochar—usually can’t afford them. Almost 63 percent of the people here live below the poverty line, making less than $130 a month on average. Yields for crops like coffee, bananas, and avocados are less than half of those on well-managed farms elsewhere in the country.

Agricultural programs funded by the Peruvian government and non-profits provide some chemical fertilizers to poor farmers, but Van Zwieten estimates that only a portion of the nutrients makes it into the crops.

Take nitrogen. It’s a building block of DNA, plant tissues, and chlorophyll, the molecule that plants use to convert sunlight into energy. A small seedling doesn’t need much nitrogen, but as the crop matures, it will need more and more to meet the demands of its budding roots, stems, and leaves. But without immediate uptake, nitrogen can escape before the plant really needs it. In the acidic soils of the jungle, nitrogen combines with a high supply of hydrogen to form ammonia, a gas that carries the nutrient into the atmosphere. Acidic conditions also slow the microbial processes that assemble nitrogen into compounds that a plant can actually absorb. “Right now, a really good farmer would be lucky to get 20 percent of the nitrogen back into the crop,” Van Zwieten says. “It’s a horrendous malgasto [waste] of this resource,” Ladd says.

(Photo: Kate Wheeling)

In the ground, biochar functions like a sponge, absorbing excess water and nutrients, including nitrogen, through tiny holes across its surface. Gradually, the nutrients work their way out of the char and back into the soil, where plants can snag them just when they need them most and before they wash away or evaporate into the atmosphere. Mixing biochar with manure or synthetic fertilizers yields a cheap, slow-release source of nutrients, giving crops a much better shot at accessing nutrients when they need them and farmers an option to spend significantly less on fertilizer.

While biomass is abundant in the jungle, fertilizer—even from animal manure—is still a scarce resource, but Ladd has an idea. “We could take the sludge from the septic tanks and combine that with green waste, so they produce a sort of hybrid biochar fertilizer,” he says. Van Zwieten cuts him off. “Human waste comes with this perception,” he says. “It’ll be a bit like trying to feed them organs.”

Ladd is still refining a recipe for biochar—the ratio of biomass to manure. With the right recipe, benefits can emerge immediately: In one study, Van Zwieten and his colleagues applied biochar to one-year-old coffee plants, and found that the roots of the plants grew upwards almost immediately to mine the char for nutrients. Aboveground effects—like changes to crop yields—take longer to emerge. In coffee, it can take years to see results; in faster growing crops, like corn, it can still take months. Ultimately, crops grown with biochar, and the extra nutrients it affords, are healthier and more resistant to diseases, including the rust fungus that is threatening coffee crops in Peru and the world over.

If this all sounds too good to be true, it is. When I ask Ladd how the project’s going, long after the cocona juice is gone, he describes it as a “dog’s breakfast”—or, in non-Australian English, a mess. For one thing, there was the fact that Ladd abandoned the cookstove portion of the project shortly before his research partners arrived in Peru. A pilot project in another jungle city, Iquitos, revealed that the women just didn’t like using the specially designed cookstoves: They were slightly smaller than traditional stoves, they took longer to cook food, and it was too much extra work to chop wood to fit inside. Ladd dropped the stove idea for this particular project in favor of Kon Tiki kilns, or funnel-shaped ovens. He started off with 260-pound steel versions, which required two to four men to cart around. Now he has farmers dig funnel-shaped pits directly into the ground, where they pile their rubbish biomass—the sticks and leaves they clear from their land and usually burn anyway—and light it up.

The recipe for biochar is not as simple. Many factors can influence the characteristics of the char the kiln produces: the type of biomass that goes in, how much, and the temperature fluctuations that occur while it all burns. No two biochar batches are exactly alike, and making biochar is as much art as science, Van Zwieten likes to say.

It’s possible to make a bad batch: If your biochar smells like a barbeque, for example, it means it has too much pyrolysis oil, which makes the biochar repel water and might hinder seed germination. But even a bad batch of biochar is better than nothing, according to Ladd. “The soil there is that fucked,” Ladd says, “the charcoal alone would do it good.”

(Photos: Kate Wheeling)

Communicating that to farmers has been his biggest challenge so far. Would you gamble your crops—your livelihood—on an unfamiliar substance evangelized by a stranger?

“The goal has always been to get the technology right and hand it over to the Peruvians,” Ladd says. He teamed up with Aprodes, a Peruvian sustainability non-profit in the forested hills of San Ramón, one of Chanchamayo’s main towns, to ease communication issues. But even that partnership hasn’t been easy. When he first arrived there and started working with Aprodes, Ladd was still handing out cookstoves. Suddenly—it seemed to Aprodes—he pivoted to Kon Tiki kilns.

Ladd is comfortable with chaos. It’s a trait that has allowed him to thrive as a scientist, but one that makes the non-profit’s leaders wary of working with him. Ladd needed Aprodes to connect with farmers, but its leaders were only slightly more willing to work with him than the people of Satipo.

Given all these logistical and scientific challenges, Ladd seems rather unfazed. According to his father, Bruce, he’s been that way since he was a child. “Brenton’s always had a mind of his own,” he says. “He just thought he was capable of doing it all. He was always taking stuff apart to see how it worked, then he couldn’t put it back together again. But it didn’t deter him. He still kept taking things apart.”

Ladd’s problem, according to Anaya de la Rosa, is that, in his pursuit to build a better forest, he often overlooks the trees. “Sometimes he misses the small details,” he says. “Aprodes have mentioned that the project is not well organized. They need order. That’s why I’m here.”

But the strained relations haven’t discouraged Ladd. “Many other people would’ve given up, but he has been extremely persistent,” Van Zwieten says.

On the way back to Lima, Ladd, Van Zwieten, and Anaya de la Rosa made another pit stop in San Ramón, to preach the promise of biochar to Aprodes employees who work directly with hundreds of farmers across the province. They headed straight to the home of Renato Gambarina, the manager of the non-governmental organization’s San Ramón research station, which provides farmers with a place to learn about growing alternatives to coffee and the basics of agricultural techniques like composting.

Over Pepsi and jalapeño-flavored Pringles, Ladd rushed through a pitch on biochar and pyrolysis in Gambarina’s living room. He showed Gambarina pictures of the three steel Kon Tiki kilns he had ready to bring to the jungle for demonstrations, swiveling his computer around on his lap so Gambarina could see the screen. Gambarina listened, wide-eyed, and nodded along, but it was not until the group reached the field site on the outskirts of San Ramón, where the non-profit has greenhouses, offices, and a classroom, that Gambarina began to understand why these gringos were giving away giant steel stoves.

Walking along the rows of greenhouses filled with Brussels sprouts, eggplant, cucumbers, jalapeños, and other crops, Anaya de la Rosa explained the big picture of the project to Gambarina. The two-fold goal of the B4SS project, he said, is the scientific evaluation of the effect of biochar on crops and the communication of any benefits to the farmer. Anaya de la Rosa guessed that, when they asked the farmers, none of them would know much about biochar. “No,” Gambarina agreed. “Starting with the name.”

Even Gambarina is a colono—or colonist—a common term in the area for anyone that comes from outside the jungle. But he’s earned the farmers’ trust in the nearly 15 years he’s spent working for Aprodes, and he agreed to introduce the foreigners to Señor Rogelio, a farmer with a parcel of land in the tiny neighboring town of Palma Pampa.

(Photos: Kate Wheeling)

And so early the next morning, they squeezed into Gambarina’s truck and followed a winding dirt road up the mountain that looms over the Aprodes field site. Without slowing down, Gambarina tapped the horn at every corner to warn drivers descending the narrow dirt road of his approach, and the engine growled louder with each switchback. After 40 minutes, the truck rolled to a stop on a muddy stretch of road in front of a green concrete house surrounded by lush vegetation.

Rogelio, who greeted the group in front of his house, looked like he stepped out of an L.L. Bean catalog onto his farm: A striped button-up and cream-colored sweater dressed up his dirt-encrusted jeans and knee-high rubber boots. His white hair peeked out from underneath a Florida Marlins baseball cap, and his laugh lines appeared prominently beneath his wire rim glasses when he asked if I was with the New York Times. He led the group up the forested hill behind his home, past his coffee orchard and nursery, to a fallow field. Ladd wanted to use the plot as an experimental site, to demonstrate what biochar could do for Rogelio and his neighbors. It was not just a matter of available land. Rogelio is a leader among the Palma Pampa farmers; if he started using biochar, the other farmers in Chanchamayo would likely follow suit.

On the hike up the steep slope, Rogelio admitted that he didn’t know what the scientists were talking about. But by the time the group descended toward his home, Rogelio had taken to calling himself Dr. Biochar.

To get back to Lima at a reasonable hour, and to avoid hitting the heaviest traffic on the two-lane highway across the Andes, the group planned to leave San Ramón by 10 a.m. Three hours after that, the group finally hit the road, steadily gaining altitude while the temperature dropped, the trees disappeared, and night fell. “The strategy on mountain roads is to use the trucks as shields,” Ladd says, crossing over two solid lines to follow a truck as it sped past the car ahead. By 10 p.m., they had made it safely to Lurín, a suburb of Lima.

Ladd’s home sits on a plot of nearly 2.5 acres of land in the mostly agricultural suburb, where he lives with his two blond daughters and a motley pack of stray dogs that roam his property waiting for the family’s pet mutt to venture out of the house. Ladd’s house and land function as both office and classroom; his graduate students come by a few days a week to work, blurring the line between his personal and professional space. Once, he caught students mixing pig manure into biochar with a spoon in his kitchen. Ladd, an intensely social person, thrives in the bustling environment.

He’s spent a not insignificant amount of time reflecting on the hurdles that prompted an Aprodes leader to ask Anaya de la Rosa—in one of several phone calls after the group’s first visit to San Ramón—if the organization couldn’t just continue the project without Ladd. “We sort of went out guns blazing, you know?” he says. “Like, giving away cookstoves and stuff to people, and it didn’t work. We’ve been a lot more careful this time. We’ve been taking smaller steps.”

In the next iteration of the project, rather than simply handing over the kilns after a spiel, Ladd’s team decided to work directly with growers to create a product and a process that they felt comfortable using. A year after the first meeting in San Ramón, Ladd returned to the Aprodes field site to lead a workshop on making biochar with Kon Tiki kilns. Twenty-eight farmers, including Rogelio, showed up. Aprodes had only invited 21 of them to participate; several others had heard about it from friends and neighbors. Not only had they learned what biochar was, now the farmers themselves were discussing the best biomass materials to include for their desired pH levels. Even Aprodes had become “super keen” on expanding its biochar activities, Anaya de la Rosa says. “They are working with other farmers near Cusco to produce and use biochar in quinoa fields,” he says. “Apparently they’ve had positive results.”

At another experimental site in the town of Villa Rica, Ladd’s students found that biochar increased both yield and profits for plots of corn. At yet another site with a banana crop in Satipo—where it seems the locals are finally warming up to Ladd—his students found that using biochar could cut the amount of fertilizer farmers need in half.

That is not to say that every experimental site proved a success; drought, fungi, and lorikeets decimated the corn that one of Ladd’s students, Sebastian, had planted on Rogelio’s fallow plot. But Rogelio, who, unsurprisingly, had been more proactive than any other farmer in experimenting with biochar himself, had added it around some of his coffee plants, and they were thriving, even as untreated coffee plants nearby showed clear signs of a fungal infection. “[Farmers] can see the results for themselves, for example, in the height of the plants,” Sebastian says. “That’s enough of an initiative for them [to use biochar], without the rigor of a ‘scientific’ experiment.”

Since planting on Rogelio’s land, Sebastian has helped set up experimental plots for four other farmers, all of whom have stopped using slash-and-burn techniques. He’s also leading hands-on workshops with dozens of others. At the last workshop, Rogelio urged his fellow farmers to try it out. “The farmers have a better sense of the product now,” Gambarina says. “Little by little, they’re using it.”

(Photo: Kate Wheeling)

These days, Ladd lets his students and Anaya de la Rosa take the lead in the jungle. He now spends the majority of his time at the university and in his home laboratory, trying to figure out how to scale up the production of biochar with Lima’s superabundance of municipal green waste and chicken manure, tackling each challenge as it comes.

A few yards behind his home sits a shed-sized oven made of boilermaker steel. It’s called a batch pyrolyzer, and it can turn up to eight cubic meters of biomass into biochar in just a few hours, with almost no greenhouse gas emissions. The prototype cost roughly $40,000 to build. Back when we first returned from the jungle, Ladd fired it up. The steel exterior glowed white hot; the concrete slab beneath the machine vibrated; and the smoke and water vapor, wafting out at metal corners twisted by the heat, carried the sweet smell of pyrolysis oil. Ladd climbed a wobbly ladder and whacked hot metal levers back and forth, trying to control the wildly fluctuating temperature within the machine. When it finished its work, Ladd found that one of the steel crates holding the biomass had warped and become stuck inside the massive oven.

Seeking shade, Ladd and Van Zwieten walked away from the oven and back toward the house. On the way in, Van Zwieten pointed out a small Norfolk pine, growing a few feet from the side of Ladd’s home. He stretched his arms wide to indicate just how wide the tree could become. “That concrete won’t be a constraint,” he said, gesturing toward the external wall of Ladd’s home. “Oh, no worries, mate,” Ladd said. “We’ll just cut out a bit of concrete.”

Soon after, Ladd figured out that he could make 10 to 20 times more biochar in a day with the Kon Tiki kilns, without the added effort of chopping up waste to fit into the batch pyrolyzer’s steel crates. Now, more than two years later, the machine stands tall and dormant on his property, and the pine still grows.

A version of this story originally appeared in the May 2018 issue of Pacific Standard. Subscribe now and get eight issues/year or purchase a single copy of the magazine. It was first published online on May 2nd, 2018, exclusively for PS Premium members.