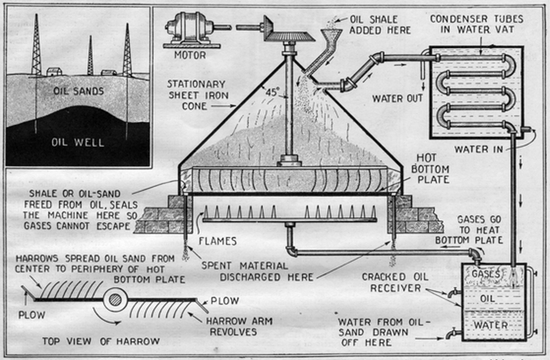

The Bowie-Gavin process of extracting oil (June 1927 issue of Science and Invention magazine)

As a non-renewable resource, we’re pretty certain that at some point we’ll run out of oil. But today—just as it was a hundred years ago—we’re not quite sure when that will come to pass.

In 1908, Teddy Roosevelt appointed the National Conservation Commission to take a proper inventory of America’s natural resources and discover areas where egregious waste was occurring. When it delivered its findings to Congress in 1909, the commission reported that the nation’s petroleum supply would last just 25 or 30 years more. Of course, the nation’s oil supply didn’t dry up in 1939; engineers developed new ways to extract oil from what used to be thought of as waste material.

The June 1927 issue of Science and Invention magazine included a short article about a process developed in 1926 by two engineers named Clifford Bowie and M. Gavin at the U.S. Bureau of Mines. In 1927, the U.S was using about 750 million barrels of oil annually (compared with about 7 billion barrels annually today), with consumption in the Roaring Twenties showing no signs of slowing down. As the article notes, when an oil field in the 1920s was considered “dry,” only about 20 percent of the usable oil had been extracted from it. The remaining 80 percent was simply soaked up into the sands.

The article reported on the new “Bowie-Gavin” process which was sure to remedy this problem:

Our sketches show the semi-commercial apparatus for distilling the oil from the shales and also from very heavy oils. The oil from this process is a cracked oil and about 20 percent of gasoline can be obtained from it.

Difficulties with other processes using the same raw material have been the plugging up of the oil vapor escape pipe by carbon which is formed when the oil is vaporized and cracked. This carbon is in the form of a hard, dense lampblack. This free carbon would also adhere to the sides of the wall of the retort and prevent the heat which is applied to the outside, from coming through and heating the oil shale and sand within.

In the Bowie-Gavin process, the oil shale or sand is dropped into the conical housing by means of a screw-operated hopper. The material falls upon the hearth plate which is heated underneath. If a heavy oil is to be treated or cracked to produce gasoline, lubricating oil and the other petroleum products, it is mixed with some inert substance like oil shale or oil soaked sand. Some of these thick oils in cool weather can be shovelled like mortar or putty, they are so viscous. These oils are not now worked, owing to the difficulty in handling them.

Today, the highly controversial process of hydraulic fracturing (often called fracking) is the latest way that companies are extracting natural gas from what used to be considered unreachable deposits. This process comes with tremendous risk to the environment, and has actually driven prices of natural gas so low that there’s currently a rush for rig operators to extract the higher priced oil. Meanwhile, Alberta has found wealth (and environmental criticism) in figuring how to tap its tar sands, the source of the oil that would flow through the controversial Keystone XL pipeline to the continental U.S.

Whether new technologies will allow us to extract another hundred years of oil no longer seems to be the primary question. We must ask ourselves whether we can live with the environmental impact of our current energy choices. And just how harshly people of the future will judge the silence of our political leaders a century hence.